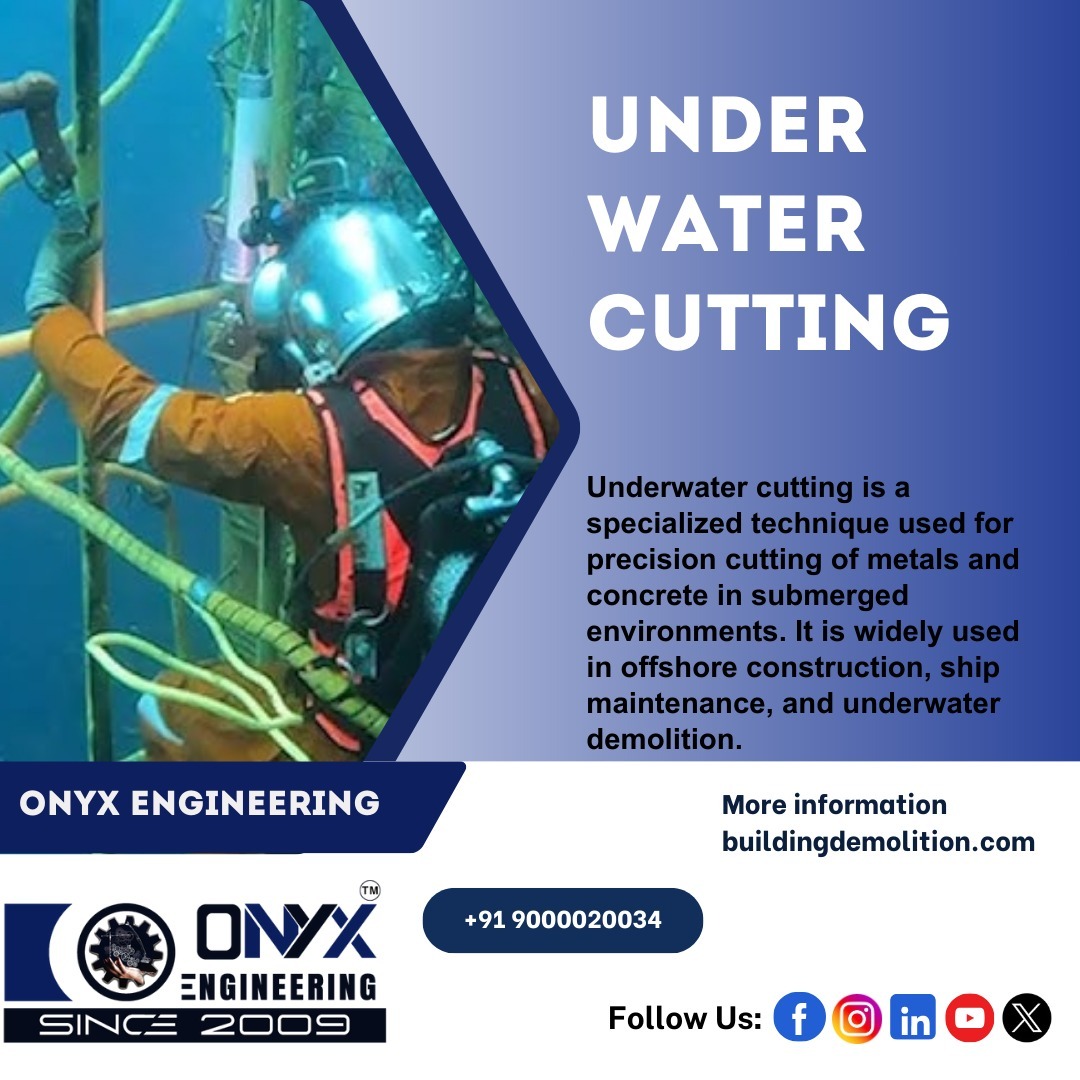

Under Water Cutting Onyx Engineering specializes in underwater cutting and related services. Their underwater cutting techniques are typically used in the marine and offshore industries, where access to submerged structures and installations is necessary. The cutting is performed using specialized equipment and processes to ensure safety, precision, and efficiency in challenging underwater environments. Here are some common underwater cutting methods that may be employed: Water Jet Cutting: A high-pressure stream of water is used to cut through materials. Water jet cutting is precise and can be used for a variety of materials, including metals, concrete, and plastics. Exothermic Cutting: Also known as “thermal lance“ cutting, this involves using a chemical reaction to generate heat that can melt or burn through metal. It's often used for cutting steel and other metals underwater. Mechanical Cutting: Underwater saws or abrasive water jet systems can be used to physically saw through materials underwater. These tools can provide a controlled, clean cut. Diamond Wire Cutting: This method uses a wire coated with diamonds to cut through concrete, rock, or metal structures underwater. It is often used in situations where traditional methods are impractical. Onyx Engineering’s specific methods and capabilities could depend on their resources and areas of focus, whether it's for oil rig decommissioning, ship hull repairs, or underwater construction.

We hate spam too.